About Hagemann Systems

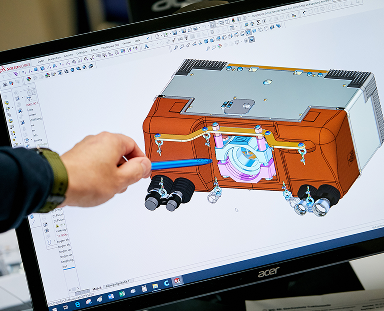

Hagemann Systems stands for innovative system solutions for the transmission and storage of electrical energy. With in-depth expertise in the processing of rubber, plastics, and conductive metals, we develop high-quality components and systems that harmonize efficiency, safety, and quality.

We don’t just think in terms of products – we think in terms of solutions: always with a focus on manufacturing processes, application practice and follow-up costs.

Discover our story

Reliable system solutions with over 80 years of experience

Our story began in the 1940s with the processing of Bakelite and the production of molded rubber parts – including products for occupational safety, seals, and components for the burgeoning automotive industry. We quickly established a reputation for producing ribbed plates for batteries – a technological field to which we remain committed today. From the molded parts manufacturer Gummi-Hagemann, we have evolved into a versatile systems provider: Hagemann Systems.

From producer to development partner

Our customers benefit from a unique combination of materials expertise, manufacturing know-how and development expertise.

Hagemann Systems has always been known for high-quality rubber and plastic parts. Over time, we have consistently expanded our portfolio – particularly to include connection technology components and cable assemblies, which are now key building blocks of many system solutions.

We know not only the theory, but also the practice – from small-batch production to large-scale series manufacturing. As a technology-driven company, we actively contribute our production expertise to product development. This results in customized solutions that optimally combine functionality, manufacturability, and cost-effectiveness.

1945

Gründung Gummi Hagemann KG

Mit der Gründung der Gummi Hagemann KG beginnt eine Unternehmensreise, die bis heute von Qualität und Beständigkeit geprägt ist.

1957

Thermoplastische Verarbeitung und Konfektionierung

Die Erweiterung um thermoplastische Verarbeitung und Konfektionierung markiert den Schritt in ein neues technisches Kompetenzfeld.

1960

Batterie-Industrie

Mit dem Eintritt in die Batterie-Industrie entwickelt sich das Unternehmen zum zuverlässigen Partner für spezialisierte Anwendungen.

2007

Gründung Hagemann Systems GmbH

Die Gründung der Hagemann Systems GmbH stärkt die Struktur des Unternehmens und ebnet den Weg für weiteres Wachstum.

2015

Hauptstandort Wuppertal

Der Umzug bzw. die Festlegung des Hauptstandorts in Wuppertal schafft eine zentrale Basis für moderne Unternehmensprozesse.

2022

Gründung Hagemann Systems Solutions GmbH

Mit der neuen Hagemann Systems Solutions GmbH entsteht ein weiterer Baustein für innovative Lösungen und eine zukunftsorientierte Ausrichtung.

Zahlen und Fakten, die für sich sprechen

Take advantage of our expertise and benefit from the highest quality.

Tiefziehen

Spritzguss

Kabelkonfektion

Blasformen

<

>

Your advantages with Hagemann Systems

Smart system solutions from a single source

Other suppliers offer components. We offer complete systems. such as battery technology: You are in need of a cooling system? We offer a system which is able both to cool and to heat and can be combined with a water replenishment system (with or without electrolyte circulation) as well as with maintenance-free connections. This is a system solution – and that’s what Hagemann Systems offers you.

Flexible series production – from prototype to large-scale production

Thanks to our integrated manufacturing capabilities within our strong corporate group, Hagemann Systems offers maximum flexibility – from development to series production. We realize the following for you:

Prototype construction for the rapid validation of new ideas

Small-batch production for pilot projects and special solutions

Large-scale production with consistently high quality and process reliability

Our customers benefit from a seamless transition between development and manufacturing – all from a single source.

Whether it’s a single item or a series: We deliver exactly what your project requires – reliably, scalably and on time.

Further development of products

Often, standard components are used that don’t meet specific requirements, which negatively impacts the quality and efficiency of the system. We can identify optimization potential just by looking at them, as with the Lugsulation. With innovative modifications, we elevate components to a new level.

Further development of manufacturing processes

By our own history, our origin is production. Thus, we are very well versed in the respective processes – especially as to plastic, rubber and metal processing. In many cases, production steps can be simplified in order to reduce costs or increase quality.

We manufacture worldwide according to uniform quality and process standards.

To ensure short delivery times, we produce in Germany; for cost-optimized projects, we utilize facilities in Eastern Europe and Asia with predictable lead times.

Customized solutions and products of any size.

Our expertise enables us to develop customised solutions for requirements of any size.

Let’s talk about your needs! Send an email to our experts now.